Commercial Trucking

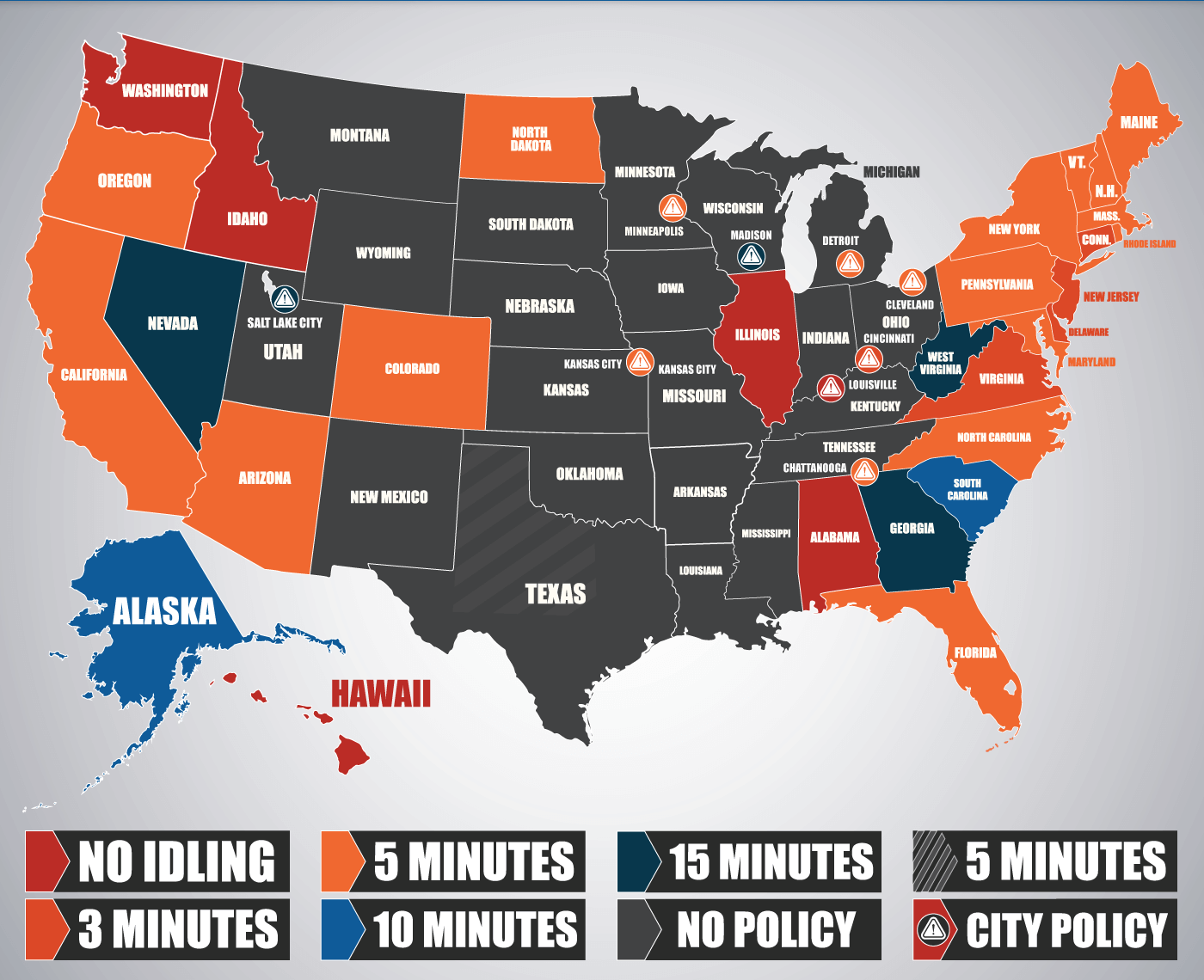

New regulations are forcing changes in the trucking industry. Anti-idle legislation prevents truckers from running their diesel engines while resting, sleeping or eating. These regulations combined with narrowing margins have refrigeration carriers seeking emerging technologies to meet the new mandates and reduce fuel consumption for their fleets.

Trucking $2.5B

Heavy-duty vehicles are less than 5% of registered vehicles on the road in the US, but they account for approximately 25% of fuel use and 20% of greenhouse gas emissions. In addition to over-the-road fuel use, trucks use a considerable amount of fuel to power auxiliary loads by idling the engine while at rest to heat and cool the cab and sleeper compartment, protect the engine in cold weather, and operate on-board electrical appliances (i.e., “hotel loads” like computer, television, radio, phone, global positioning system, microwave, mini-refrigerators, and coffee makers). The US EPA estimates that idling a heavy-duty truck’s engine consumes about 1 gallon of diesel fuel per hour.1 Therefore, a typical long-haul truck without idle reduction technology that idles 8 hours a day for 300 days per year can be expected to use 2,400 gallons of diesel fuel for idling each year, which is over 10% of the truck’s total fuel use. This idling results in fuel costs of $9,600/year or $800/month when diesel fuel is $4/gallon.

ZAF’s NiZn battery provides 2x the capacity, 2x the power and 2x the life over lead acid: In a battery operated Auxiliary Power Unit (APU) field test, the OEM replaced eight (8) lead acid batteries with four (4) ZAF NiZn batteries. The objective was to provide enough energy to support the 10-hour crew rest in the new sleeper comfort system. While the 8 lead acid batteries were only able to support eight hours, ZAF’s 4 NiZn batteries provided the full 10-hour requirement.

Multiple Benefits of NiZn:

- Lower First Cost – 8 lead acid batteries at $300 each ($2,400) were replaced by 4 NiZn batteries at $500 each ($2,000) providing a first cost savings of $400 per truck.

- Lower O&M – NiZn provides 2x the cycle life of lead acid batteries which reduces the O&M costs over the life of the truck. Currently, lead acid batteries are being replaced every 12-18 months.

- Extended Operating Times – NiZn extends no-idle periods from 8 hours to the required 10 hours. For lead acid to support the required 10 hours they would have to add 2 batteries which would add over 150 pounds in battery weight and would require a redesign of the battery compartment.

- Safe and Fully Recyclable – as the trucking industry faces growing pressure to become more sustainable, NiZn is a technology that eliminates lead while being cost effective, safe, recyclable and environmentally friendly.

- Reduced Weight – replacing 8 lead acid batteries with 4 NiZn, there is over 400 pounds of battery and 50 pounds of structure. If you add in the 150 pounds from the 2 additional lead acids required for extended operating times, this adds up to over 600 pounds! This means the truck frees up 600 pounds in payload!

- Platform for Growth – The current Class-8 battery boxes are built for 8 Group 31 batteries. As power loads continue to grow, NiZn provides plenty of capacity to meet that demand without reengineering the battery box.

In addition to solutions for long haul trucks, the NiZn technology provides similar benefits for other industrial motive applications such as lift trucks, refrigerated trailers and material handling equipment.